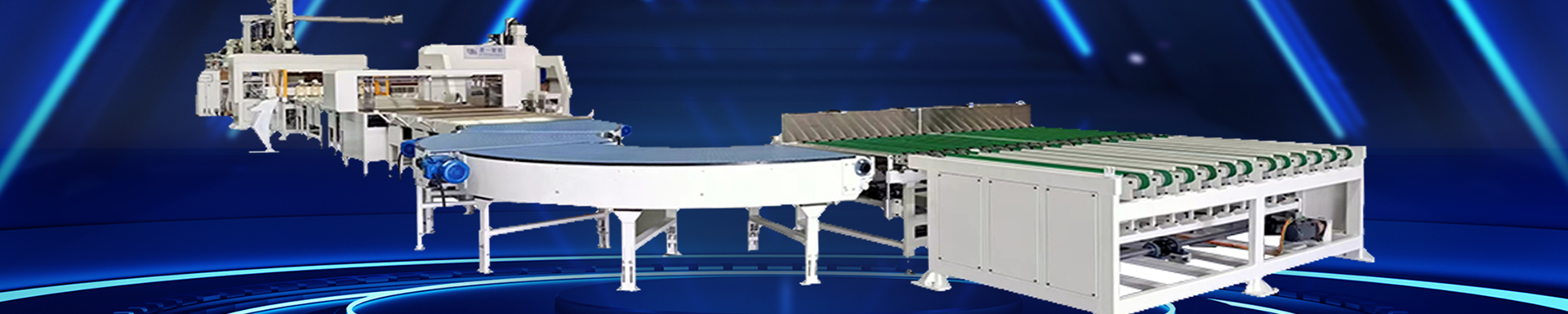

Automatic carton rotary wrapper

The automatic carton rotary wrapper is a piece of equipment specially designed for efficient packaging and is widely used in various industries. This type of wrapper can quickly and accurately complete the packaging of cartons through high-tech rotary packaging technology.

Wrapper

A wrapper refers to a mechanical device used to package products. The automatic carton rotary wrapper is a typical wrapping machine that can significantly improve packaging efficiency and quality through its advanced design and functions. The equipment can automatically complete the carton packaging process, reducing the need for manual operations and thus improving production efficiency.

rotary wrapper

Rotary wrapper refers to equipment that uses rotational motion to complete the packaging process. The automatic carton rotary wrapper utilizes this principle to achieve uniform and tight packaging effects through the rotation of the carton inside the wrapping machine. Rotary packaging technology not only increases the packaging speed, but also ensures the firmness of the packaging.

carton wrapping machine

The carton wrapping machine is specially used to pack cartons of various specifications. The automatic carton wrapping machine can adapt to cartons of different sizes and shapes, providing flexible packaging solutions. This kind of wrapping machine is widely used in electronic products, food, medicine and other industries, and is favored for its efficiency and reliability.

automatic strapper

The automatic strapper is one of the indispensable equipment on the packaging production line. Automatic carton rotary wrappers usually integrate automatic packaging functions and can pack the cartons after packaging is completed. The automatic strapper ensures the safety and stability of cartons during transportation through automated packaging operations. Using automatic strapper not only improves packaging efficiency, but also reduces the waste of packaging materials.

Advantages of automatic carton rotary wrapper

The automatic carton rotary wrapper has several significant advantages. First of all, this equipment can greatly increase the packaging speed and meet the needs of mass production. Secondly, automated operations reduce manual intervention and reduce labor costs. In addition, rotational packaging technology ensures the uniformity and firmness of packaging and improves product protection. Finally, the automatic carton rotary wrapper is easy to operate and has low maintenance costs. It is an indispensable equipment on the modern packaging production line.

In short, the automatic carton rotary wrapper provides efficient and reliable packaging solutions for various industries by integrating advanced packaging technology and automated operations. Whether used in electronic products, food or pharmaceutical industries, this wrapper can significantly improve packaging efficiency and ensure the safety of products during transportation.

This is the Special-purpose equipment for using the stretching film automatically wropping the goods on the pallet for antidust,anti-wet and anti-bulk.It can protect the goods,save the packaging cost,reduce workers labor intensity,and increase the packaging effect.

Goods in pallet put on the conveying line to the wrapping section,according to the setting wrapping parameters, wrapper will be automatically started and filming to achieve the wrapping process continuously,after finishing,film automatically be cut and welding.And goods automatically conveyed to the next section. Next goods start the circulating wrapping.

The machine is composed of Rotary arm driving section,Film rack lifting secton,mechanism rack, safty device,film rack, automatically filming and break section(national patent),Rotary arm wrapper automatic control system.Safety locks and Electrical control system.

| Tech in ical Parameters |

| Wrapping ObjectSpec. |

| Wapping Object Spec | L(1000-1400)*W(1000-1300)*H(500-2000)mm |

| Object Weight | MAX1500kg |

| Pallet size | Customized |

| Machine Technical Parameters |

| Load Weight | 1500Kg(max) |

| Wapping Speed | 30-35托/小时Pallet/Hour(max) |

| Conveying Speed | 206mm/s |

| Conveying Platform Height | Customized |

| Rotary Arm Speed | 15r/m(max) |

| Power | ≈3KW |

| Machine Weight | 1500Kg |

| Working Voltage | 380VAC/3phase5wires/50Hz |

| Gas consumption | 1000ml/min |

| Pheumatic Working Pressure | 0.5~0.6MPa |

| WrappingMaterial |

| Stretching Film Material | LLDPE Stretching Film |

| Fim Width | 500mm |

| Fim thickness | 20-35m |

| Max.Diameter | 260mm |

| Paper Core inner bore | 76mm |

| Paper Core Length | 520mm |