automatic carton stacker

Introduction

The automatic carton stacker is an efficient industrial device designed for automated handling and stacking of cartons. It plays an important role in modern production lines and can significantly improve production efficiency and reduce labor costs.

Functions and features

The main function of the automatic carton stacker is to stack finished cartons in a preset arrangement to facilitate subsequent handling and storage. Features include:

Efficient automation: Through programming control, automatic carton stacker can achieve fully automated operation without manual intervention, greatly improving the efficiency of the production line.

Multifunctional application: not only suitable for ordinary box stacker, but also can handle various paper bundle stacking machines to meet the needs of different industries.

High accuracy: The automatic carton stacker uses advanced sensors and positioning technology to ensure that each carton can be stacked accurately and in place.

Saving space: The stacker can stack cartons into a compact shape, saving storage space and reducing storage costs.

Safe and reliable: Equipped with multiple safety protection measures to prevent accidents and ensure the safety of operators.

Application scenarios

Automatic carton stacker is widely used in various industries, especially in the fields of logistics, food and beverage, electronic products and daily chemical products. The following are some specific application scenarios:

Logistics industry: In logistics warehousing centers, automatic carton stackers can quickly and efficiently stack cartons of various sizes neatly to facilitate subsequent transportation and sorting.

Food and beverage industry: Food and beverage production lines often require a large number of packaging and stacking operations. Automatic carton stacker can help companies improve production efficiency and ensure that products are not damaged during transportation.

Electronic products: In the production process of electronic products, a large number of packaging boxes need to be stacked. The accuracy and efficiency of the automatic carton stacker can greatly improve the operating efficiency of the production line.

Daily chemical products: Daily chemical products such as detergents, toothpastes, etc. need to be stacked after packaging. The automatic carton stacker can be adjusted according to the characteristics of different products to meet diverse stacking needs.

future development

As the level of industrial automation continues to improve, automatic carton stackers will be increasingly used in various fields. Future development directions include:

Intelligence: By introducing artificial intelligence technology, automatic carton stacker can achieve higher-level intelligent operations, such as automatically adjusting stacking strategies and monitoring equipment status in real time.

Modular design: Modular design will make the box stacker easier to maintain and upgrade, extend the service life of the equipment, and reduce the company's operating costs.

Environmental protection and energy saving: In the future, paper bundle stacking machines will pay more attention to environmental protection and energy saving, and reduce energy consumption and environmental pollution through optimized design and use of new materials.

In short, the automatic carton stacker, as an efficient automation equipment, has broad development prospects and application potential. Driven by continuous innovation and technological progress, it will make greater contributions to the improvement of production efficiency and cost reduction in various industries.

System Feature

Automatic robot palletizing speed: 23-34bundles/min

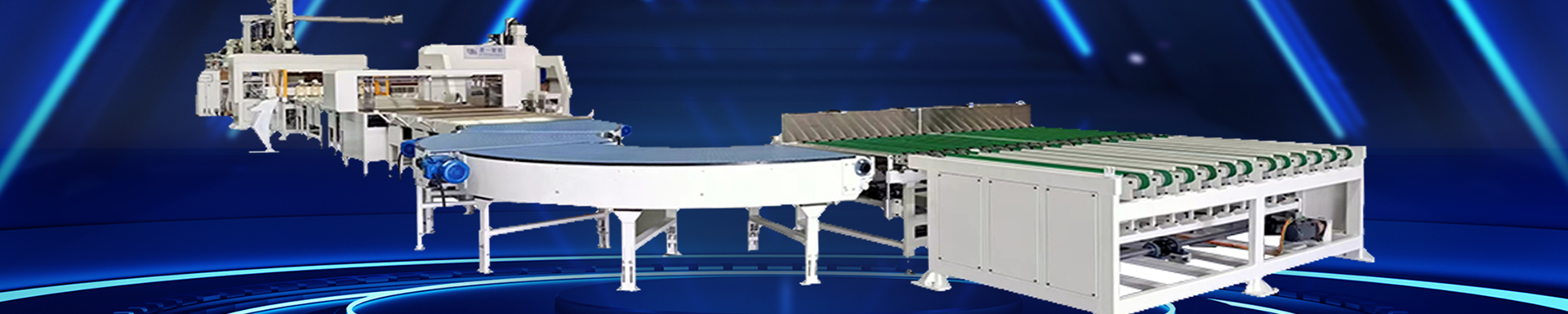

Automatic robot palletizer system: It is mainly used in the stacking procedure after making the boxes with bundles, is the replacementof traditional manual stacking . It can reduce the dependence on labor, avoid the loss of personnel caused by heavy-intensity work, and stabilize production efficiency. It has many advantages such as efficient handling, accurate movement, neat stacking, intelligentstacking, convenient operation, high safety, high integration and intelligent operation,etc.

The configuration of our automatic robot palletizer system can be divided into: light duty roller conveyor system +automatic pallet magazine + fast positioning device + robot palletizer + automatic paper pading device + four-sidedsquaring system + heavy load conveyor system, which can be applied to different brands of FFG, such asBOBST/SHINKO/MITSUBISHI/DONGFANG/TAIYI/ DINGLONG,etc . Now our sales already occupied the main domesitc high-end market.

| Technical Parameters &Analysis |

| Max. Carton Size | 1200 W x 1000 L x 250 H mm |

| Min. Carton Size | 380 W x 260 L x 50 H mm |

| Max. BundleWeight | 30 KG |

| Bundle Quantity | 5~20 PCS/Bundle捆 |

| RobotArm Palletizing Capacity |

| Max. Stacking speed | 22times/min | Min. Grabbing height | 50mm |

| Max.StackingBundlesspeed | 28-34 bundles/Min | Max. Grabbingwidth | 1200mm |

| StackingPosition Precision | ‘+-3mm | Min. Grabbing width | 380mm |

| Max. Grabbingweight | 180 KG | Max. Stacking area | 1800W*1800L mm |

| Max. Grabbing height | 400mm | Max. Stacking Height | 1800mm |

| Pallet |

| Pallet Max. Size | 1300 W x 1400 W x 150 H mm |

| Pallet Min. Size | 1200 W x 1000 W x 150 H mm |

| Pallets Change time | 8~10S |

| Pallet store Height | 2000 mm |

| Pallet Position Precision | 10 mm |

| Max.Conveying load | 1000 KG/m2 |

| Padding paper action |

| Paper Pick and Place time | 3S |

| Padding paper size | Max . size same as the pallet |

| Padding paper requirement | size neat and fixed |

| Squaring Movement |

| Max. Squaring Size | 1800Wx1800Lx2000H |

| Min. Squaring Size | 850W*x850Lx300H |

| CyclingTime | 3-4秒/Seconds |