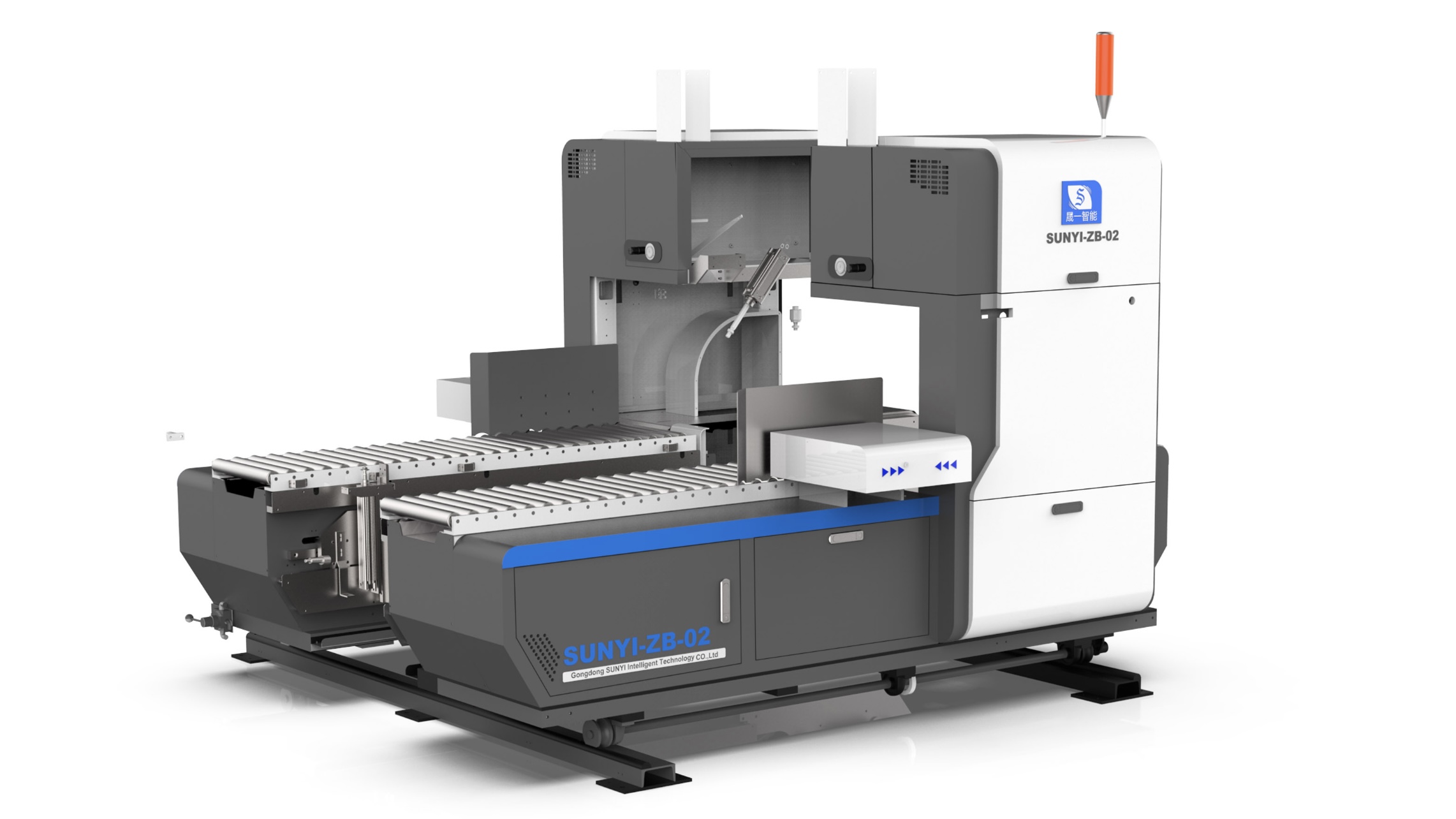

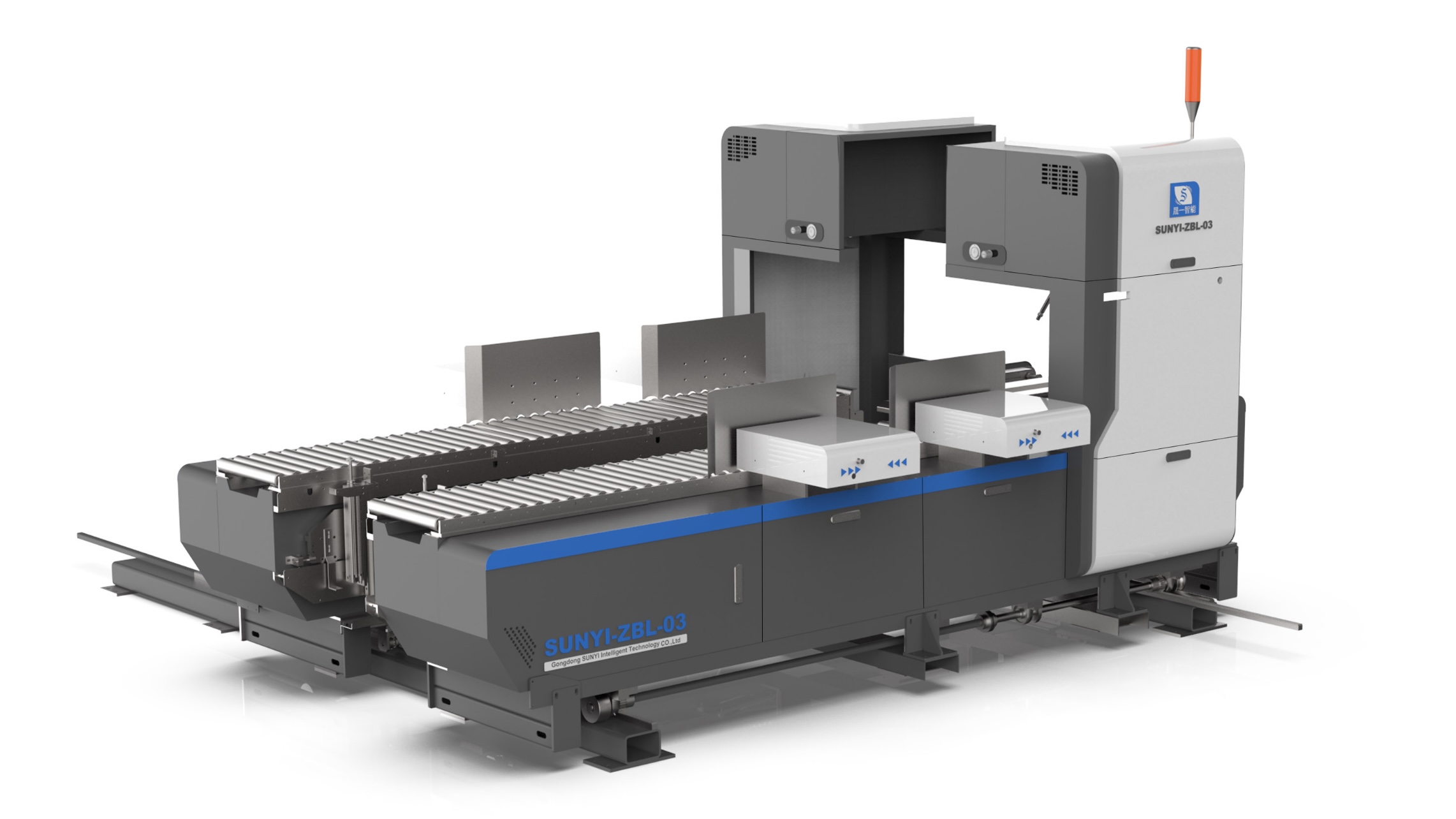

Automatic Corrugated Carton Strapping Machine

Automatic corrugated strappler is an indispensable equipment in the modern packaging industry. With the continuous increase in logistics and transportation needs, enterprises have higher and higher requirements for packaging equipment. Automatic strapper came into being in this context and is widely used in the strapping of cartons, parcels and other items.

Automatic strapper can efficiently complete the strapping of cartons, improve packaging efficiency and reduce labor costs. This equipment is easy to operate. Just place the carton in the designated position and start the machine to complete the strapping process. The strapping machine realizes the fastening and strapping of cartons through automatic belt feeding, tightening, hot melting and cutting, ensuring that they will not loosen or spread during transportation.

Corrugated strappler is particularly suitable for the field of carton packaging. It uses high-strength plastic belts or steel belts for strapping, and can choose suitable strapping belts according to different packaging needs. The carton bundling machine ensures that each carton is properly protected through precise strapping force adjustment without damaging the box body due to excessive strapping.

In practical applications, automatic strappers are widely used in packaging production lines in industries such as food, beverages, electronic products, and daily necessities. Enterprises can choose different models of automatic strappers according to the layout of the production line and product characteristics to achieve the best packaging effect. For example, in a fast packaging line, the use of a high-speed, high-efficiency strapper can greatly improve production efficiency and meet the needs of mass production.

In short, the automatic corrugated strappler plays an important role in the modern packaging industry. It not only improves packaging efficiency and reduces labor costs, but also ensures the safety of products during transportation through reliable strapping effects. In the future, with the continuous advancement of technology, the automatic strapping machine will play a greater role in more fields and bring more convenience and benefits to enterprises.

The touch screen operation of the entire computer is fast, convenient, and easy to maintain.

Fully automatic multi-point lubrication and refueling

PE rope fully automatic servo double rope packaging machine, which can be connected to fully

automatic box gluing and nailing machines for automatic packaging

High speed printing linkage line, which can adjust the size of the entire machine and automatically adjust

the machine. It can achieve online linkage function with a robotic arm, and can be fully automatically

packaged at high, medium, and low speeds.

Multiple manual box ordering machines can be assembled and connected for automatic packaging.

Can integrate multiple semi-automatic box nailing machines and box pasting machines for automatic

packaging.

Save labor (equivalent to 4-8 labor) and reduce the impact of human factors on production; Save

production costs (the cost per meter of PP rope is about 3-5 times that of PE rope)

The packaging speed is more than twice that of traditional PP belt fully automatic packaging machines