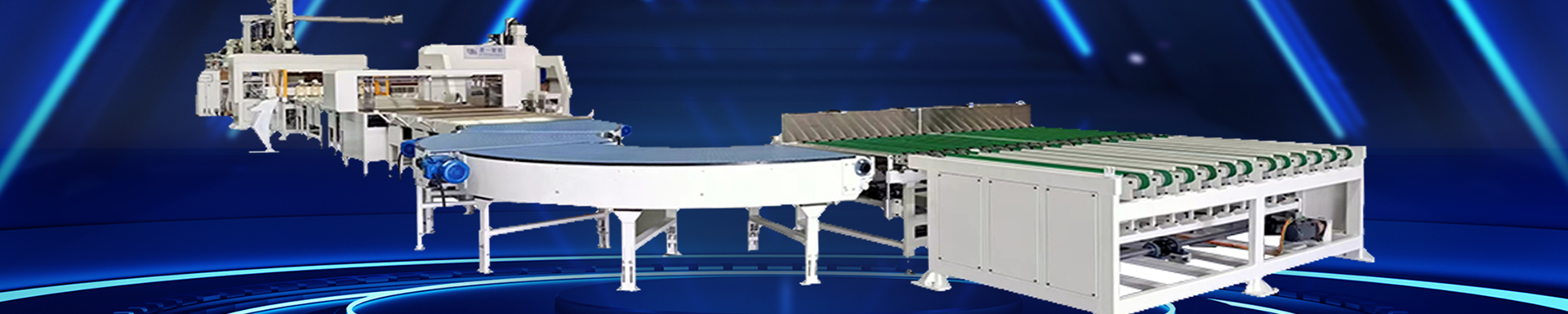

Automatic Roller Transfering Conveyor

Automatic roller conveyor is an advanced equipment widely used in various production lines and logistics systems, especially for efficient transportation of boxes, pallets and other goods. As a key component, roller conveyor relies on the movement of a series of rotating rollers to transfer goods from one location to another. Through its automated design, roller conveyor can achieve continuous and stable material transportation, greatly improving production efficiency and reducing labor costs.

Automatic roller conveyors are particularly widely used in modern warehousing and logistics centers. For example, carton transfering conveyor is designed for boxes of various sizes and weights, whether it is a lightweight carton or a heavy wooden box, it can complete the transfer task smoothly and efficiently. When the box slides on the roller, due to the friction of the roller surface and the uniform rotation of the roller, it can ensure that the goods do not deviate from the track and arrive at the predetermined location accurately.

Automatic conveyors play an important role in many industries. From electronic product manufacturing to food processing, from pharmaceutical logistics to express sorting, automatic conveyors can provide enterprises with efficient and reliable material handling solutions. These systems can not only reduce the errors of manual operation, but also ensure the safe transportation of goods while greatly improving the processing speed.

In addition, the intelligent control system of the automatic roller conveyor is also one of its core advantages. Modern conveyors are equipped with advanced sensors and control software, which can monitor various parameters of the conveying process, such as speed, load and position, in real time. When an abnormal situation is detected, the system can respond quickly, adjust the operating status or issue an alarm to ensure the smooth progress of the entire production process.

In short, the application of automatic roller conveyors in industrial automation and logistics systems not only significantly improves the efficiency and accuracy of material handling, but also saves a lot of labor costs for enterprises. Through continuous technological innovation and optimization, roller conveyors will continue to meet the growing needs of various industries and provide strong support for more efficient automated production and logistics management.

System Feature

Automatic robot palletizing speed: 23-34bundles/min

Automatic robot palletizer system: It is mainly used in the stacking procedure after making the boxes with bundles, is the replacementof traditional manual stacking . It can reduce the dependence on labor, avoid the loss of personnel caused by heavy-intensity work, and stabilize production efficiency. It has many advantages such as efficient handling, accurate movement, neat stacking, intelligentstacking, convenient operation, high safety, high integration and intelligent operation,etc.

The configuration of our automatic robot palletizer system can be divided into: light duty roller conveyor system +automatic pallet magazine + fast positioning device + robot palletizer + automatic paper pading device + four-sidedsquaring system + heavy load conveyor system, which can be applied to different brands of FFG, such asBOBST/SHINKO/MITSUBISHI/DONGFANG/TAIYI/ DINGLONG,etc . Now our sales already occupied the main domesitc high-end market.

| Technical Parameters &Analysis |

| Max. Carton Size | 1200 W x 1000 L x 250 H mm |

| Min. Carton Size | 380 W x 260 L x 50 H mm |

| Max. BundleWeight | 30 KG |

| Bundle Quantity | 5~20 PCS/Bundle捆 |

| RobotArm Palletizing Capacity |

| Max. Stacking speed | 22times/min | Min. Grabbing height | 50mm |

| Max.StackingBundlesspeed | 28-34 bundles/Min | Max. Grabbingwidth | 1200mm |

| StackingPosition Precision | ‘+-3mm | Min. Grabbing width | 380mm |

| Max. Grabbingweight | 180 KG | Max. Stacking area | 1800W*1800L mm |

| Max. Grabbing height | 400mm | Max. Stacking Height | 1800mm |

| Pallet |

| Pallet Max. Size | 1300 W x 1400 W x 150 H mm |

| Pallet Min. Size | 1200 W x 1000 W x 150 H mm |

| Pallets Change time | 8~10S |

| Pallet store Height | 2000 mm |

| Pallet Position Precision | 10 mm |

| Max.Conveying load | 1000 KG/m2 |

| Padding paper action |

| Paper Pick and Place time | 3S |

| Padding paper size | Max . size same as the pallet |

| Padding paper requirement | size neat and fixed |

| Squaring Movement |

| Max. Squaring Size | 1800Wx1800Lx2000H |

| Min. Squaring Size | 850W*x850Lx300H |

| CyclingTime | 3-4秒/Seconds |