Robotic Palletizer

In recent years, with the rapid development of automation technology, Robotic Palletizer has been widely used in logistics and manufacturing. Robotic Palletizer achieves efficient and accurate cargo stacking and handling through precise robotic manipulators and advanced control systems, greatly improving production efficiency and operational safety.

First, the robotic palletizing machine can be flexibly operated in various complex environments by using robotic manipulators. The high degree of freedom of the robotic manipulator enables it to easily complete the tasks of grabbing and placing at various angles and positions. This flexibility enables the robot palletizer to handle items of different sizes, weights and shapes, and adapt to different production line requirements.

Second, the robot palletizer is highly automated. Through pre-programming and sensor feedback, the robot palletizer can realize a fully automated cargo stacking process. The operator only needs to set the parameters in the initial stage, and the machine can automatically complete the stacking task according to the set path and plan. This not only reduces manual intervention and improves operational efficiency, but also reduces the risk of human operational errors.

In addition, while improving production efficiency, the robotic palletizing machine also greatly improves operational safety. Traditional manual palletizing requires workers to engage in repetitive heavy physical labor for a long time, which is prone to musculoskeletal diseases and work-related injuries. The introduction of robotic palletizing machines can effectively reduce the labor intensity of workers and reduce the occurrence of work-related accidents. Robots can operate stably in high-risk environments, ensuring the continuity and safety of operations.

Robotic palletizing machines are not only used in the production lines of manufacturing industries, but also play an important role in the field of logistics and warehousing. Modern warehousing centers use robotic palletizing machines to sort and stack goods, which not only improves warehousing efficiency but also optimizes space utilization. Robotic palletizing machines can intelligently plan stacking plans according to the characteristics of different goods and maximize the use of storage space.

In summary, robot palletizer, as an advanced automation equipment, is gradually changing the traditional production and logistics methods. Its high efficiency, flexibility and safety make it widely used in all walks of life. With the continuous advancement of technology, robot palletizer will play a more important role in the future and bring more convenience and benefits to various industries.

System Feature

Automatic robot palletizing speed: 23-34bundles/min

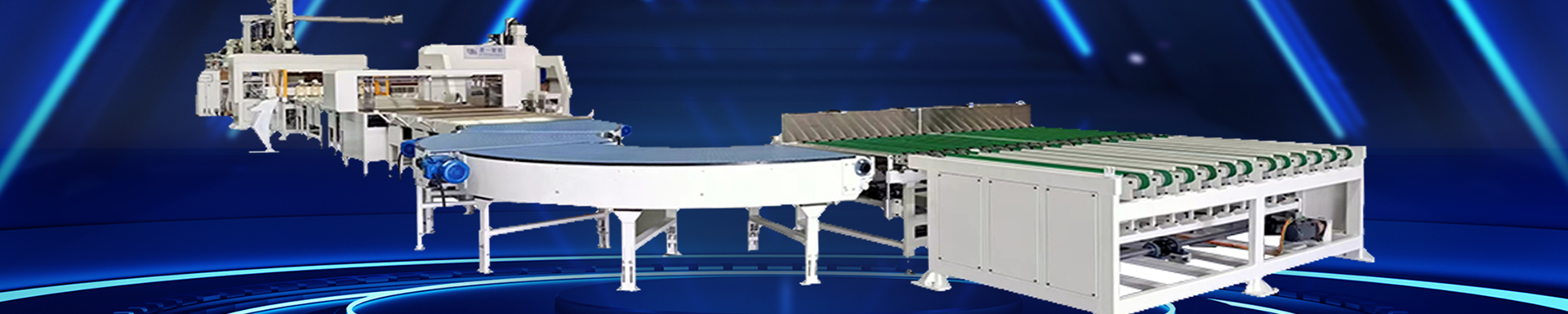

Automatic robot palletizer system: It is mainly used in the stacking procedure after making the boxes with bundles, is the replacementof traditional manual stacking . It can reduce the dependence on labor, avoid the loss of personnel caused by heavy-intensity work, and stabilize production efficiency. It has many advantages such as efficient handling, accurate movement, neat stacking, intelligentstacking, convenient operation, high safety, high integration and intelligent operation,etc.

The configuration of our automatic robot palletizer system can be divided into: light duty roller conveyor system +automatic pallet magazine + fast positioning device + robot palletizer + automatic paper pading device + four-sidedsquaring system + heavy load conveyor system, which can be applied to different brands of FFG, such asBOBST/SHINKO/MITSUBISHI/DONGFANG/TAIYI/ DINGLONG,etc . Now our sales already occupied the main domesitc high-end market.

| Technical Parameters &Analysis |

| Max. Carton Size | 1200 W x 1000 L x 250 H mm |

| Min. Carton Size | 380 W x 260 L x 50 H mm |

| Max. BundleWeight | 30 KG |

| Bundle Quantity | 5~20 PCS/Bundle捆 |

| RobotArm Palletizing Capacity |

| Max. Stacking speed | 22times/min | Min. Grabbing height | 50mm |

| Max.StackingBundlesspeed | 28-34 bundles/Min | Max. Grabbingwidth | 1200mm |

| StackingPosition Precision | ‘+-3mm | Min. Grabbing width | 380mm |

| Max. Grabbingweight | 180 KG | Max. Stacking area | 1800W*1800L mm |

| Max. Grabbing height | 400mm | Max. Stacking Height | 1800mm |

| Pallet |

| Pallet Max. Size | 1300 W x 1400 W x 150 H mm |

| Pallet Min. Size | 1200 W x 1000 W x 150 H mm |

| Pallets Change time | 8~10S |

| Pallet store Height | 2000 mm |

| Pallet Position Precision | 10 mm |

| Max.Conveying load | 1000 KG/m2 |

| Padding paper action |

| Paper Pick and Place time | 3S |

| Padding paper size | Max . size same as the pallet |

| Padding paper requirement | size neat and fixed |

| Squaring Movement |

| Max. Squaring Size | 1800Wx1800Lx2000H |

| Min. Squaring Size | 850W*x850Lx300H |

| CyclingTime | 3-4秒/Seconds |