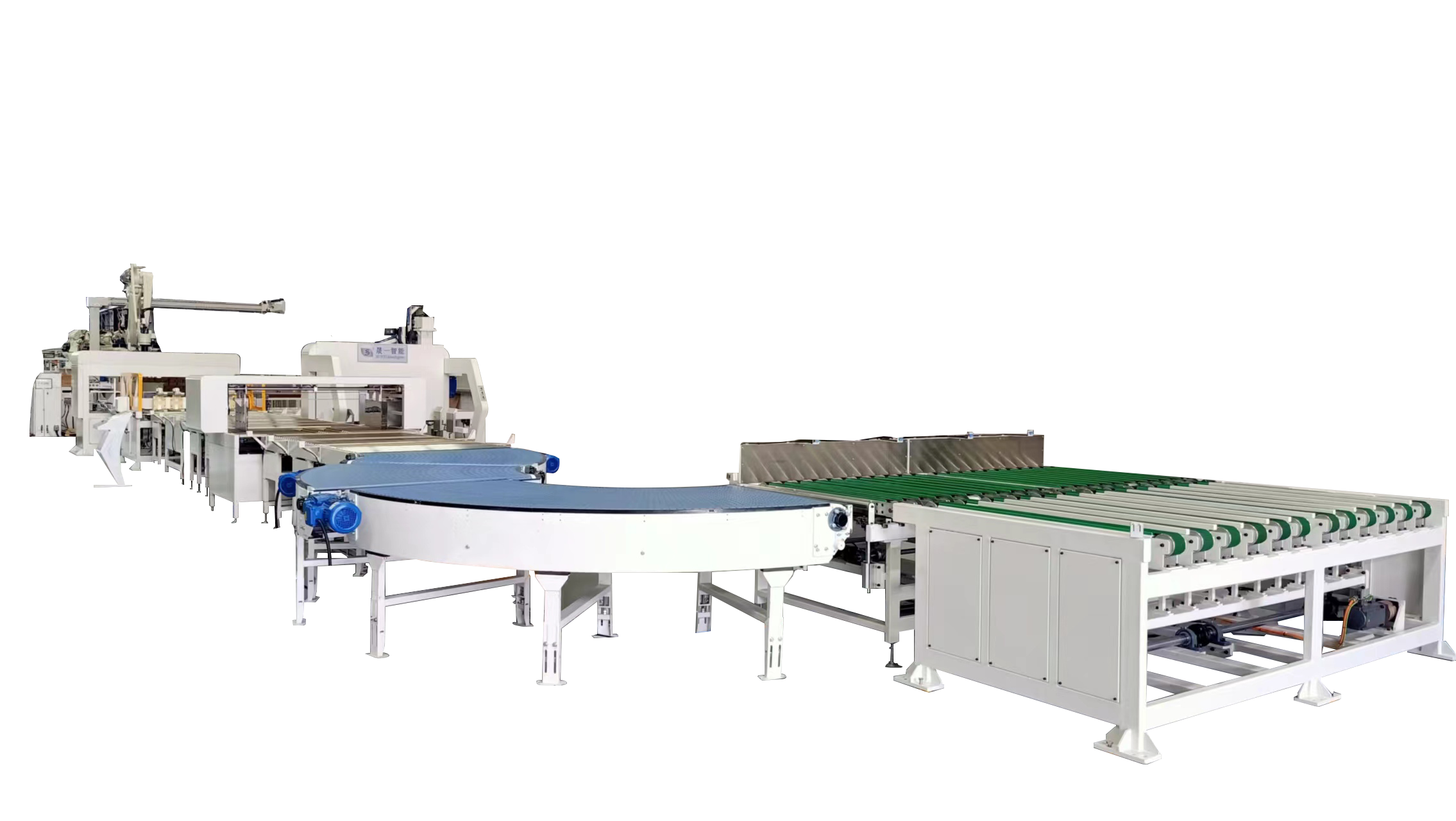

Carton Robot Palletizing Equipment

With the development of modern manufacturing and logistics industries, the application of automation equipment in various fields has become more and more common. In this process, palletizing robots and palletizer equipment, as key automation solutions, have played a vital role. In particular, carton palletizing equipment has improved efficiency and precision in various packaging and transportation processes.

A palletizing robot is a device used to automatically stack products on pallets. Traditional manual palletizing is not only inefficient, but also prone to unstable stacking or damage to products. In contrast, the palletizing robot can accurately control the stacking position and angle of each carton through programming, ensuring that each layer is neat and stable. This not only improves palletizing efficiency, but also reduces labor costs and the risk of product damage.

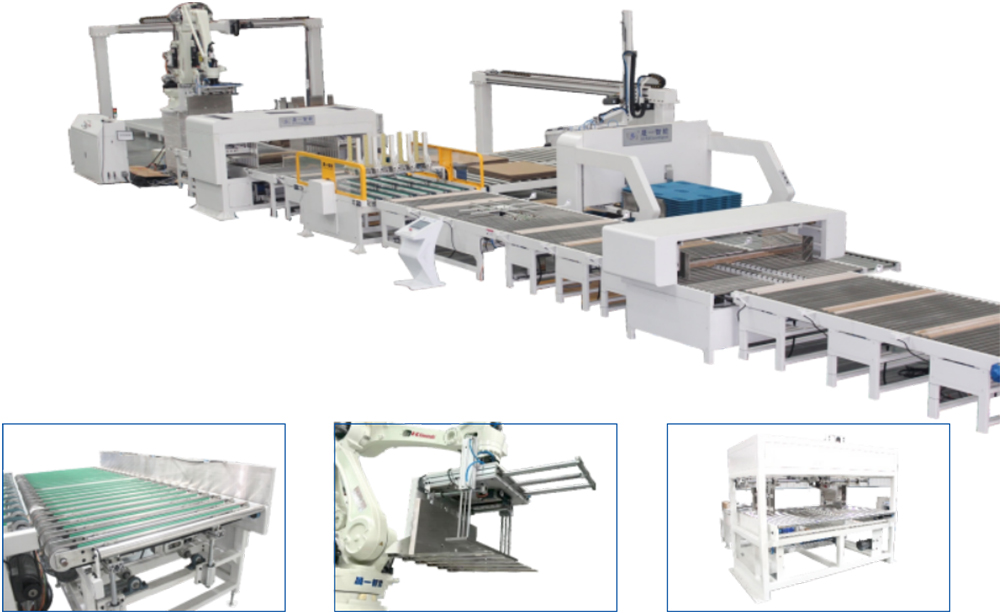

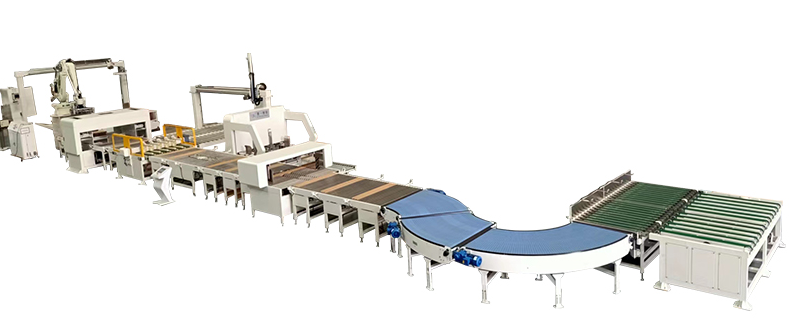

There are many types of palletizer equipment, which can be customized according to different needs. For carton palletizing equipment, common types include robotic arm palletizers and gantry palletizers. Robotic arm palletizers use flexible robotic arms to grab and stack cartons, and are suitable for cartons of many different sizes and shapes. The gantry palletizer uses a gantry structure to achieve a wide range of carton handling, which is suitable for high-frequency and large-volume palletizing needs.

Carton palletizing equipment is particularly widely used in logistics and warehousing. In industries such as express delivery, food, and beverages, carton palletizing equipment can significantly improve packaging efficiency. Taking the food industry as an example, the products on the production line enter the carton through a conveyor belt, and then are automatically stacked by the carton palletizing equipment, thus realizing an integrated automated process from production to warehousing. This not only improves production efficiency, but also reduces the hygiene problems that may be caused by manual operation.

In short, the application of palletizing robots and palletizer equipment not only improves the production efficiency and logistics speed of enterprises, but also provides reliable technical support for the development of automation in all walks of life. In the future, with the continuous advancement of artificial intelligence and machine learning technologies, carton palletizing equipment will show its strong application potential in more fields.

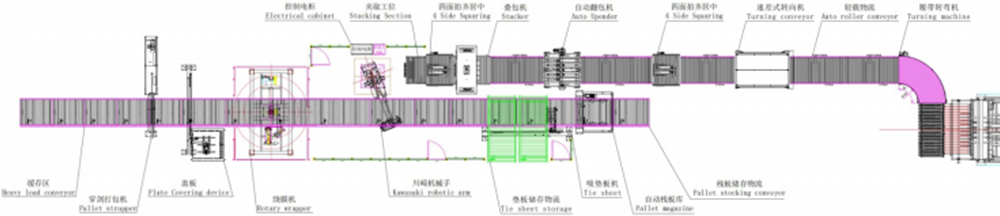

| Automation equiment- robot palletizer system |

| Technical parameters & Analysis |

| Max.Carton Size |

|

| 1200Wx1000Lx250H mm |

| Min.Catron Size |

|

| 380Wx260Lx50H mm

|

| Max. Bundle Weight |

|

| 30kg

|

| Bundle Quantity |

|

| 5~20Pcs / Bundle |

|

| Robot Arm Palletizing Capacity |

| High Speed Single Bundle Max Stacking speed | 23±1 times/Min | Min.Grabbing height | 50mm

|

| High Speed Double Bundle Max Stacking speed | 38±1 times/Min | Max.Grabbing width | 1200mm

|

| Stacking Position Precision | ±3mm | Min.Grabbing width | 380mm |

| Max.Grabbing weight | 180kgs Including gripper weight | Max.Stacking area | 1600W*1600L.mm |

| Max.Grabbing Height | 400mm | Max.Stacking Height | 2200mm including Pallet |

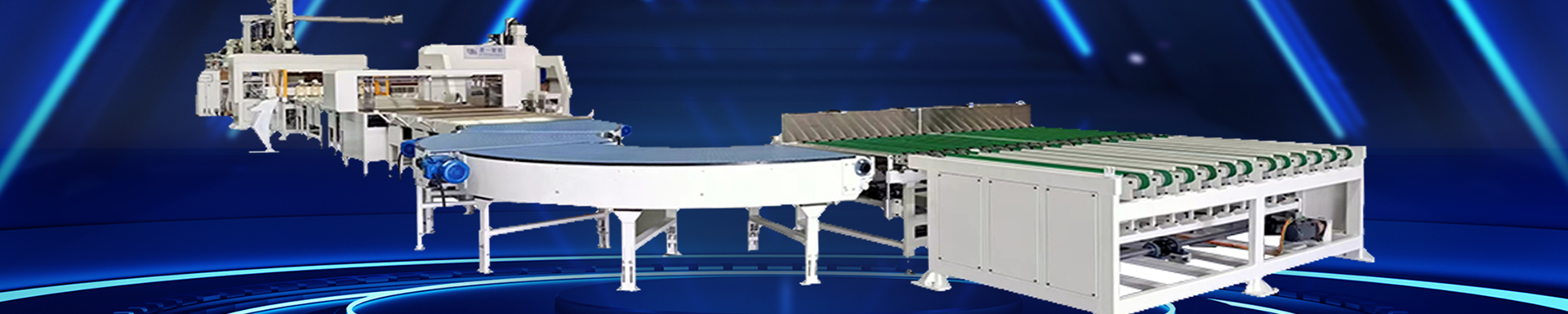

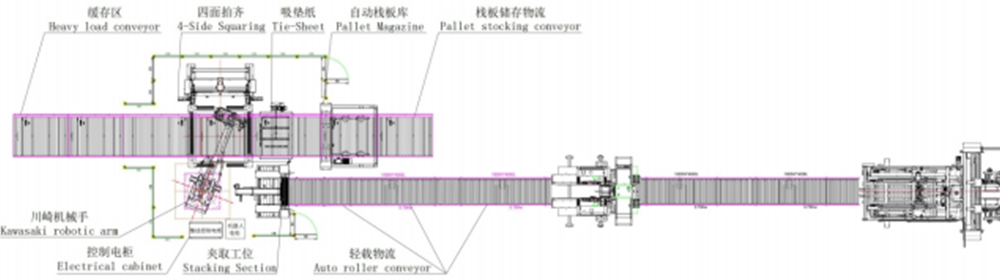

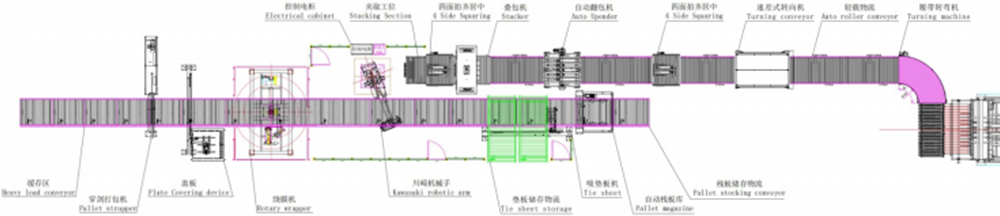

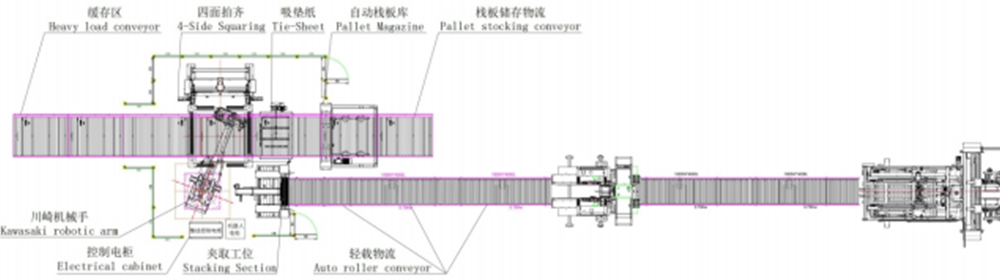

Inline solution 1 : Robot palletizer system + 4 - side squaring device( standard solution) - Applies to: Auto gluer/ Auto stitcher/ Printer FFG

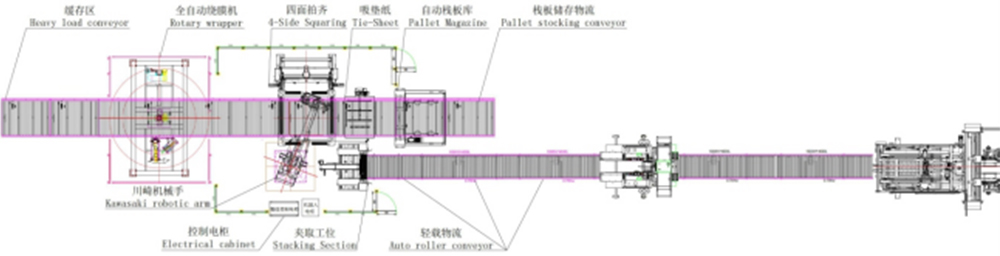

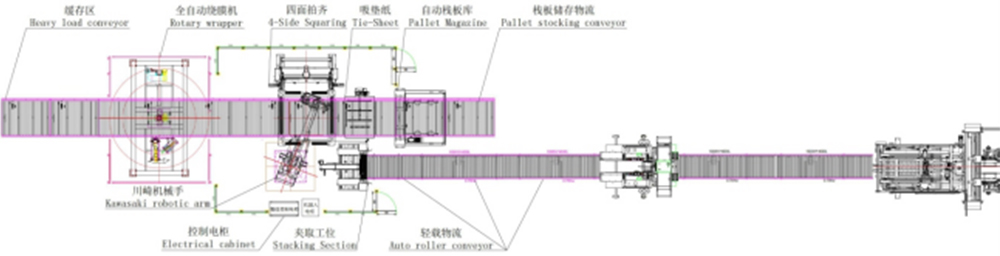

Inline solution 2 : Robot palletizer system + 4 - side squaring device+ Rotary wrapper- Applies to: Auto gluer/ Auto stitcher/ Printer FFG

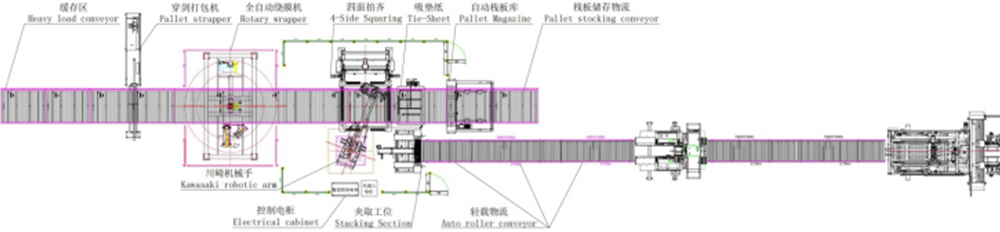

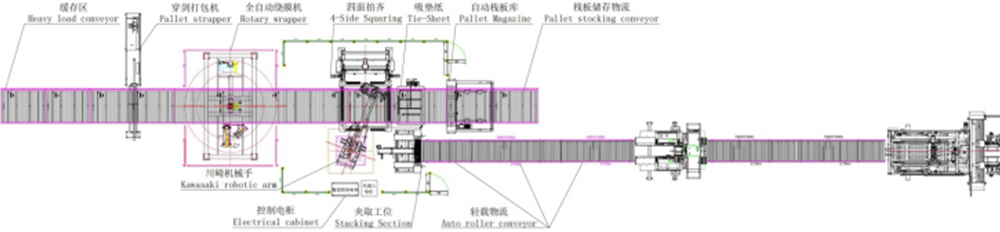

Inline solution 3: Robot palletizer system+4 side squaring device + Rotary wrapper +Pallet strapper-Applies to : Auto gluer/Auto stitcher/Printer FFG

Inline solution 4: RDC robot palletizer system +Rotary wrapper + Pallet strapper-Applies to RDC line palletizing: Top Printing Slotting Die Cutting Counting Stacker/Auto Flat Die Cutting machine