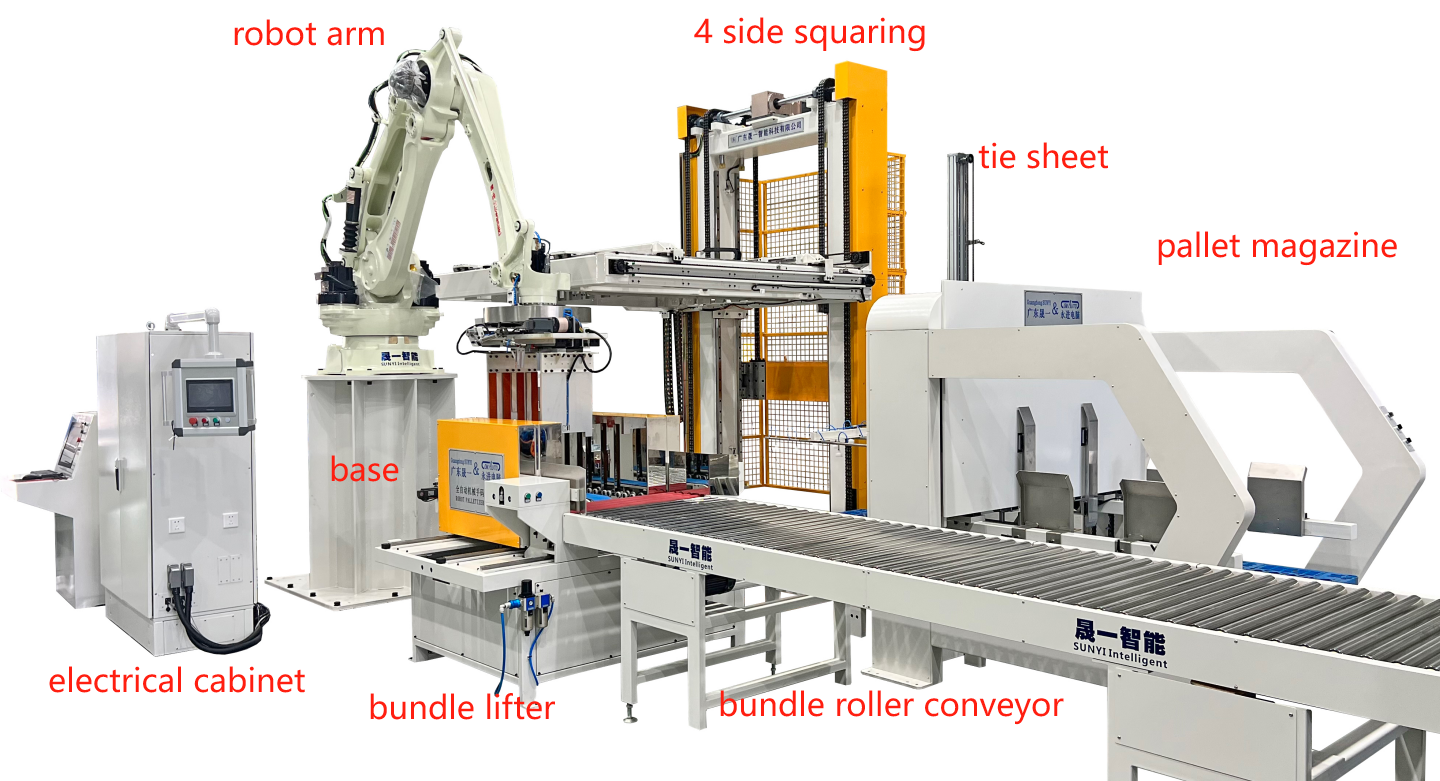

SUNYI robot palletizer system is a whole intelligent palletizing system including conveyors, bundle lifter, robot arm, tie sheet, pallet magazine and 4 side squaring. See the picture below:

Technical parameters:

| System Performance list and Analysis |

| Max. Carton Size | 1200 W x 1000L x 250 H mm |

| Min. Carton Size | 380 W x 250 L x 50 H mm |

| Max. Bundle Weight | 30KG |

| Box Qty/bundle | 5-20pcs |

| Robot Arm Stacking Ability: (Pallet size: 1200W*1200L, 4 Bundles/Layer; (485W*635L*125H) |

| High Speed Single Bundle Max. Stacking Time | 23±1 times/Min |

| High Speed Double Bundle Max. Stacking Time | 40±2 times/Min |

| Stacking Position Precision | ±3 mm |

| Max.Grab Weight | 180 KG |

| Max.Grab Height | 400 H |

| Min.Grab Height | 50H |

| Max.Grab Width | 1200mm |

| Min.Grab Width : | 250mm |

| Max. stacking area | 1650*1650mm |

| Max. stacking Height | 2000mm not incl. pallet |

| Pallet magazine: |

| Wood pallet Size : | 1200Wx 1000L/800x H150 mm |

| Sheet Changing time: | 8-10 S |

| Position Precision | 10mm |

| Max. Conveying Load : | 1000 KG/m2 |

| Squaring Movement |

| Max. Squaring Size | 1650*1650*2000Hmm |

| Min. Squaring Size | 600L*850*350Hmm |

| Cycling Time : | 2-3S |

Why use Robot palletizer?

| Manual palletizing | VS | Robot palletizer |

| 8-9 bundles/min | Speed | 23 ± 1 Bundles/min |

| 40 ± 2 Bundless/min |

| 3-5 hours/shift | shift time | 24 hours |

| emotional, difficult to manage |

| easy to manage |

| Low | Efficiency | high |

| disorganized operation | Palletize operation | Standard operation |

| Height: 1.8m(incl.pallet) | Pallet utilization | 2.35m(incl.pallet) |

| 16 layors/pallet | Save space for warehouse | 19-20 layors/pallet |

| More and more cost for long term | cost | More and more cost saving |

Corrugated cardboard box robot palletizing system

Corrugated cardboard boxes play an important role in modern logistics and packaging industries, and their safe and effective stacking and transportation are key to ensuring the integrity and efficiency of goods. Robot palletizing system, as an advanced automation solution, is widely used in the stacking and palletizing process of corrugated cardboard boxes. This article will discuss and describe in detail the "robot palletizing system" and its related keywords.

Overview of Robot Stacking System

The Robotic Palletizer System is an automated device specifically designed to stack corrugated cardboard boxes or other packaging boxes onto pallets in a predetermined manner. These systems typically consist of one or more industrial robots equipped with advanced vision systems and control software, capable of achieving high-precision stacking operations.

Working principle of corrugated cardboard box palletizing robot

The corrugated cardboard box palletizing robot utilizes advanced vision systems and 3D space planning algorithms to determine the optimal stacking method by analyzing and identifying the position, size, and direction of the boxes. The robotic arm of the robot can accurately grasp and place each box, ensuring the stability and neatness of stacking.

Components of Robot Stacking System

A typical robot palletizing system includes the following key components:

1. Robot arm: A mechanical arm responsible for grabbing and placing boxes, typically with multi axis motion degrees of freedom and high-precision motion control capabilities.

2. Vision system: Camera and image processing software used to identify and locate boxes, ensuring that the robot can accurately perform stacking tasks.

3. Control system: including control software and interfaces, used to guide the movement and operation of the robot, ensuring the smooth progress of the entire palletizing process.

4. Conveyor system: A conveyor line or belt system that transports boxes to be palletized to the robot's work area.

The advantages and applications of robot palletizing system

The robot palletizing system has significant advantages over traditional manual palletizing methods:

Improving efficiency and productivity: Robots can work continuously and complete more stacking tasks in the same amount of time, increasing the efficiency and production capacity of the production line.

Reduce labor costs and human errors: The automated palletizing process reduces labor costs and can avoid errors and losses caused by human operations.

Improving the safety of the work environment: reducing the opportunities for employees to perform repetitive actions and handling, and lowering potential safety risks in the work environment.

The robot palletizing system is widely used in the packaging process of corrugated cardboard box production and logistics centers. Whether in the food and beverage industry, electronics industry, or general consumer goods industry, these systems can effectively handle boxes of different sizes and shapes, providing reliable packaging solutions for businesses.

Future development trends and technological innovation

With the advancement of automation and robotics technology, robot palletizing systems are constantly evolving and improving:

A smarter visual system: utilizing deep learning and artificial intelligence technologies to enhance the robot's ability to recognize box shapes and features, further optimizing stacking efficiency and accuracy.

Multi robot collaboration system: Introducing multi robot collaboration technology to achieve more complex palletizing task allocation and execution, adapting to the needs of multi variety and small batch production.

Sustainability and Environmental Protection: Adopting the design concept of energy conservation and emission reduction, optimizing system energy consumption, reducing resource waste and environmental impact.

conclusion

As an important component of modern automated packaging industry, robot palletizing system not only improves production efficiency and packaging quality, but also promotes the sustainable development of enterprises in the fiercely competitive market. With the continuous advancement of technology and changes in market demand, these systems will continue to play a critical role in providing innovative and efficient solutions for logistics and packaging in various industries worldwide.

Top of the form

Bottom of the form